Visit the Craftsman Home Remodeling Website

Friday, March 17, 2006

Stairwell Wainscot, Concrete Poured, Work Stopped, Gone Surfing

• We are laying out the stairwell wainscoting. It will be Honduran Mahogany with 6 distinct layers to give it a depth effect. Just wait and see...

• Drainage was put in on the North side of the house.

• Concrete was poured on the North side so we can now build the block wall for the planter.

• Two carpenters and the electrician are surfing and camping at Big Sur for the last two days. My GC is sick with food poisoning and Dave, the finish carpenter is on another job for 2 days. In other words, NO WORK FOR THE LAST 2 DAYS IN THE HOUSE. How in the world will we finish in time when things like this happen?

Thursday, March 2, 2006

Gamble House Lights, Floor Issue, Fireplaces, Ebony Plugs, Kitchen Tile

• I created the stained glass for the light in the December 18th blog post only to find out that half of them were too small. After another week of stained glass work, I finished and my fingertips were raw. I brought the glass panels to Old California Lantern Company for installation and received the lights about 2 weeks ago. They are absolutely stunning!

• The floors are installed. Lesson learned - make sure the installers verify that the door still opens before the whole thing is laid!!!

• The kitchen, laundry room, and master bathroom American cherry cabinets have been stained with Jel'd Stain Red Mahogany by Wood Kote.

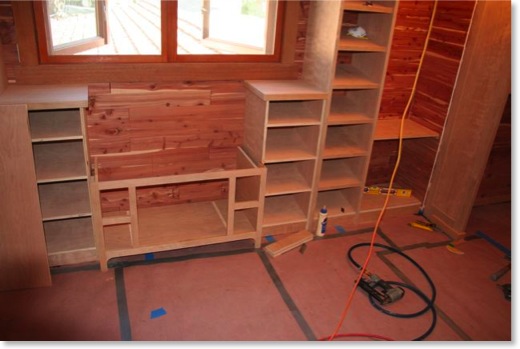

• The walk-in closet cabinets are almost complete.

• The master bedroom fireplace is covered with a beautiful Batchelder tile from Mission Tile West in Santa Monica.

• The living room entertainment center is built and ready for finishing.

• Dave Barlow is installing the ebony plugs in the scarf joints around the house.

• The living room fireplace is having Moonlight flagstone installed right now. It's a very slow process as each piece is being chiseled to the right dimensions. Look on the left part of the mantel and you can see my sugar cube mockup of the stone corner. I made this to make sure they understood how I wanted the 45-degree angles handled.

• The appliances will be installed tomorrow.

• Clear-coating of the mahogany will start in about 2 weeks followed by painting the walls and ceiling.

• Glass tile from Mission Tile West has been installed in the kitchen. It looks amazing!

Well, I'm going to start uploading the pictures now and then I'm off to Kauai for my 40th birthday.

Sunday, December 18, 2005

Wall Sconce Stained Glass, Wood Floors Being Installed

• I'm really busy now creating the stained glass for some authentic Gamble House reproductions. The stained glass will be different and my own design. I'll tie that into the front door window whenever I get around to it. Go to Old California Lantern Company to see the best Arts & Crafts lanterns. I went in there and 3 1/2 hours later I outfitted my entire house.

• The hardwood floors are being installed right now. It is long-length (8'-16'), quarter-sawn, 5"-wide, Brazilian Cherry. We are having a slight bevel put between the planks to give it an older look. The floor will be stained black, sanded, and then stained with a green dye to subdue the bright reds associated with Brazilian cherry.

Thursday, December 15, 2005

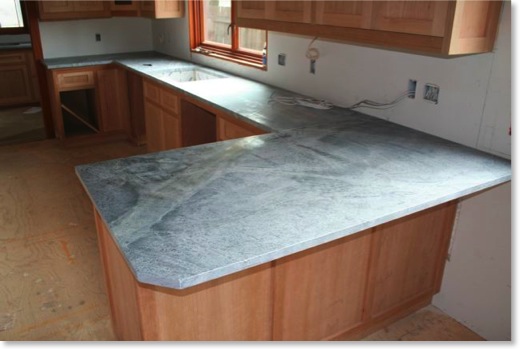

Soapstone Counter Installation

Below is a play-by-play of the installation.

These guys drove in from Arizona, and within 2 days measured, fabricated, and installed the soapstone countertops.

These slabs are HEAVY at 20 lbs/sq ft.

There is a 3/8" overlap of the sink. The holes for the faucet, soap, drinking water, and vent are drilled.

Black epoxy is mixed up to join the soapstone pieces and fill in any voids.

A ding is repaired with the special epoxy. After it dries you can't even see it.

Even through the talcum powder layer you can see the caramel vein showing through.

Soapstone installation is messy work.

Soapstone is much denser than granite and can't be stained. However, it is soft enough so that hand sanding can be accomplished to smooth the edges.

This looks gray now but wait until it's oiled.

I oiled the soapstone with mineral oil. It's shiny because it's still wet. When dry, it will have a matte finish.

The counter looks great! The door to the laundry room has a "Delta" pattern in it.

Thursday, November 3, 2005

The Finishes are Going In

• The master bathroom has been tiled and looks great!

• Cherry cabinets have been installed in the kitchen, master bath, and laundry room. Unfortunately, the kitchen sink cabinet was 3/4" off center from the window. The cabinet had to be shortened by 3/4" on both ends to keep it symmetric and centered on the window.

• I have purchased the soapstone slabs for the kitchen and laundry room from Soapstone West in Escondido, CA.

• Brazilian Cherry floors have been ordered from Dutko Hardwood Floors in Lawndale, CA and will be installed the first week of December. Talk about a backlog.

• The fireplace mantel has been installed and stained. Plaster will go above it and Moonlight flagstone will go below. It will be cut into manicured blocks of varying size.

• Actual work has started on the staircase. There was a lot of planning to get to this point.

• The hot tub has been delivered. We're just waiting for power now.

• The Golden Busckskin flagstone has been installed on the front and back patios.

• The green slate has been installed on the balconies.

• Paint samples are all over the walls. I hear they will start within 2 weeks with the paint.

• Interior doors are installed and stained.

Friday, September 2, 2005

Garage Door Installed, Interior Primed, Bathroom Floated, Ceiling Beams Installed

• All interior doors have been ordered but we have to wait about a month. Expected delivery is 9/14/05.

• The garage door was installed.

• Interior of house and garage has had two coats of primer applied.

• Master bathroom has been floated and is ready for tile.

• The ceiling beams are being installed single-handedly by Dave Barlow. The planning for this was extremely difficult as there is quite a bit of wood and detail in a Craftsman style house. We are designing the layouts on the fly for the ceiling, crown moulding, plate/picture rail, floor trim, wainscoting, and staircase. All of these pieces tie together as one entire wood 'system'. Our design of this is staying about one or two steps ahead of the build. One problem is that we don't have our wood floors in yet so we can't build the jambs up from the floor.

Friday, August 5, 2005

Camera Broken, Drywall Taped and Sanded, Starting Staircase, Siding Complete

• Drywall is sanded and just about ready for primer.

• Dave Barlow is working the staircase and will be doing other fine carpentry in the house. He is creating mockups of everything out of MDF (fiberboard) prior to cutting the real wood.

• All shingle and stone siding is installed.